SeaWolf VIII

With 6DOF movement and a full complement of software and hardware systems, SeaWolf VIII is AquaPack's most advanced AUV platform

The latest iteration of our vehicle, SeaWolf VIII, was created with the goal of improving platform stability and consistency to enable future development work. This iteration drew from the lessons learned from previous iterations, and focuses on simplicity and maintainability throughout the design. SWVIII's systems are divided into Mechanical, Electrical, and Software subgroups.

Electrical

SeaWolf VIII's electrical system puts modularity at the forefront and can be broadly broken down into three main functions: Power, Control, and Logic.

Power

Batteries

SW8 utilizes two 4s 10,000mAH LiPo batteries to power the entire system. The LiPo chemistry was chosen for its high energy density and relatively constant voltage output throughout the discharge cycle.

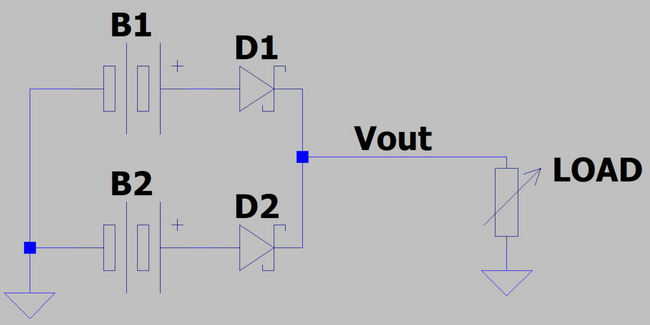

Load Balancing Board (LBB)

The use of two batteries enables high performance output for longer periods of time. However, the batteries cannot simply be wired in parallel due to safety concerns. The Load Balancing Board uses an ideal diode controller to safely split the robot’s current draw between the batteries.

Solid State Relays

Just as important as supplying power is controlling when power is supplied. SW8 uses two solid state relays wired in series to control power input to the thrusters. Each relay acts as a switch, one controlled by a physical toggle on the outside of the robot, and one by a software-actuated signal. Their “AND” configuration ensures that the thrusters are powered only when allowed by both of those sources.

Regulators

SW8 uses an array of voltage regulators to step the power down from battery voltage (~15.2V) down to the voltage levels required by individual components. This includes several 5V UBEC regulators, and a 12V buck-boost converter. In order to reduce the transient effects of thruster inrush current on the primary computer (NVidia Jetson), it is powered by a 12V SEPIC and 5V buck-boost in series.

Logic

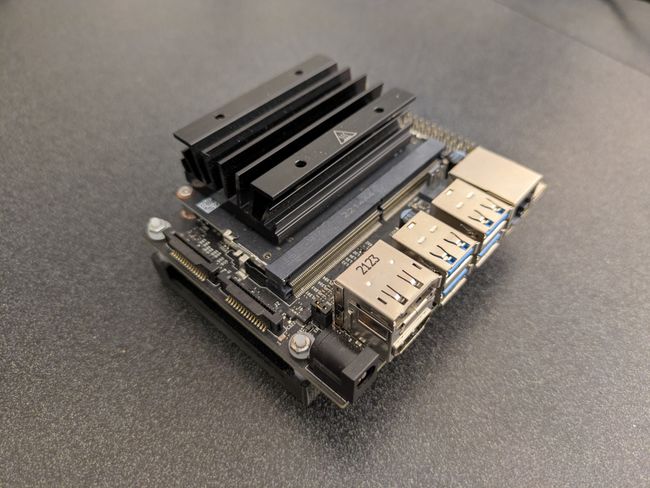

Nvidia Jetson

The Jetson is SW8’s primary computational unit. It runs the robot’s high-level software and serves as the programmer’s interface to the electronics system.

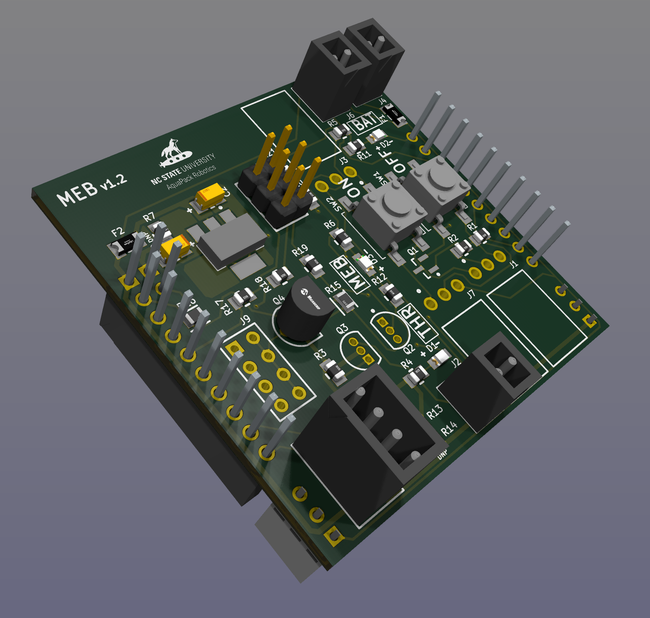

Main Electronics Board (MEB)

The MEB is the primary logic controller for the electronics system. Among its functions are:

- Receiving user commands from the Jetson via UART

- Sending actuator commands to the Manipulation Systems Board via I2C

- Power Switching

- Controlling External LEDs

- Monitoring Leak Detectors

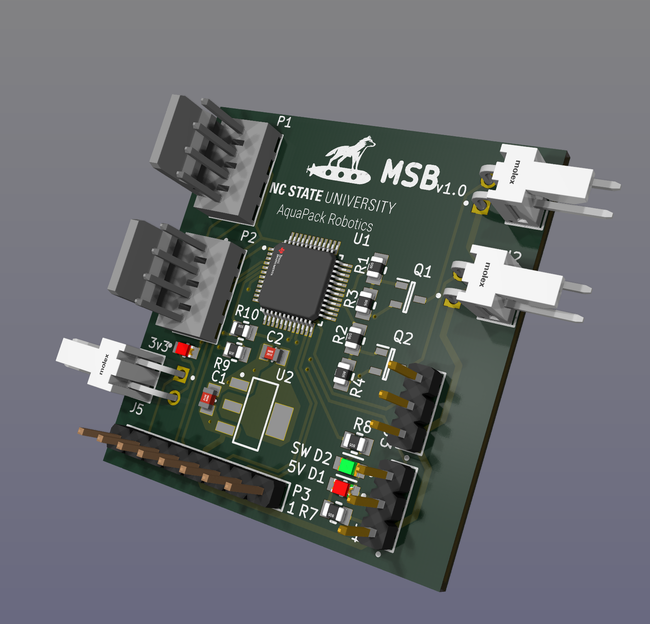

Manipulation Systems Board (MSB)

The purpose of the MSB is to drive SW8’s external mechanical systems. This entails sending PWM signals to the torpedo launcher servos and a logic signal to enable/disable the dropper’s electromagnet.

Control

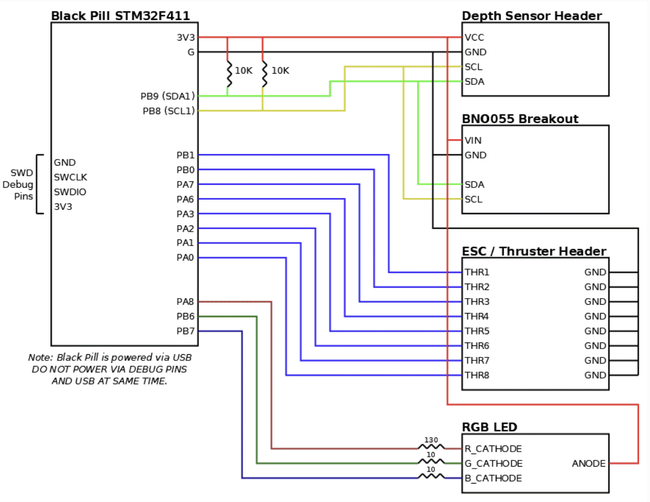

Control Board

The Control Board handles vehicle locomotion. It receives high level movement commands from the Jetson Nano, and converts them into individual PWM signals to control the power output of the thrusters. It utilizes a PID controller with state information from the onboard IMU to adjust thruster setpoints.

Electronic Speed Controllers (ESCs)

The onboard ESCs receive PWM signals from the control board, which encode thruster speed commands, and convert them into current through the motors three phases.

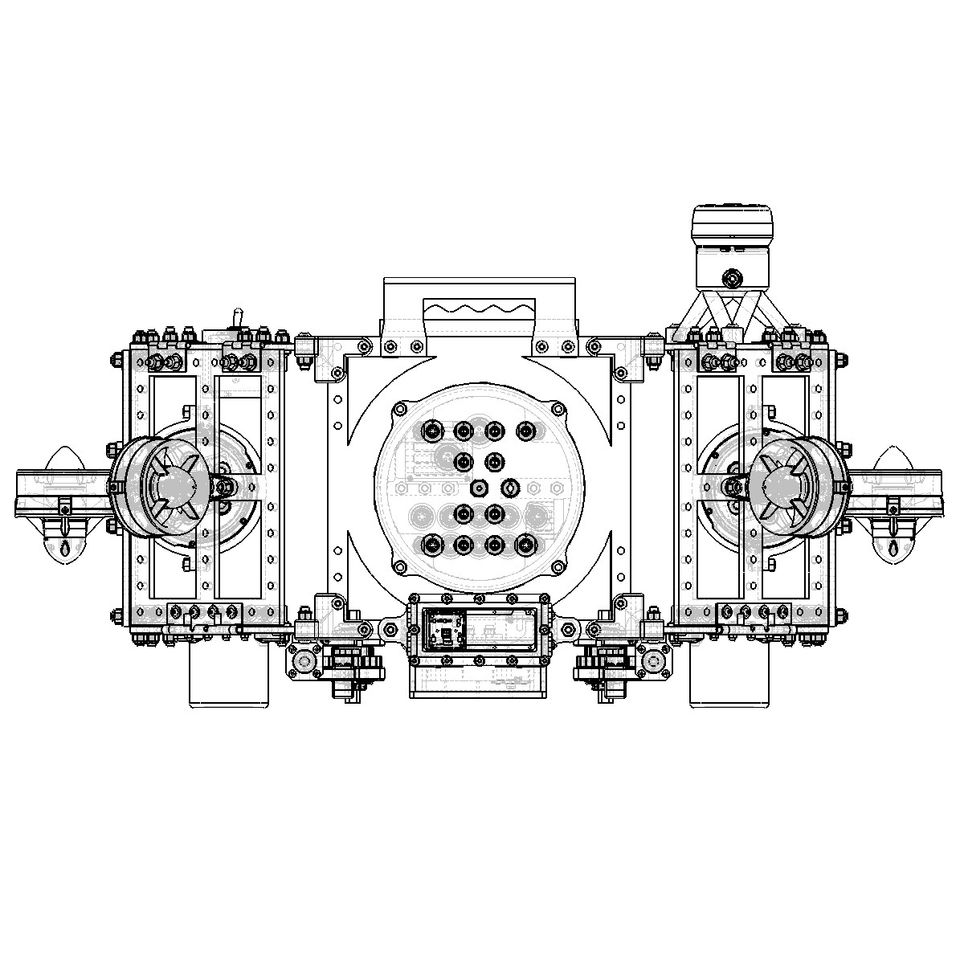

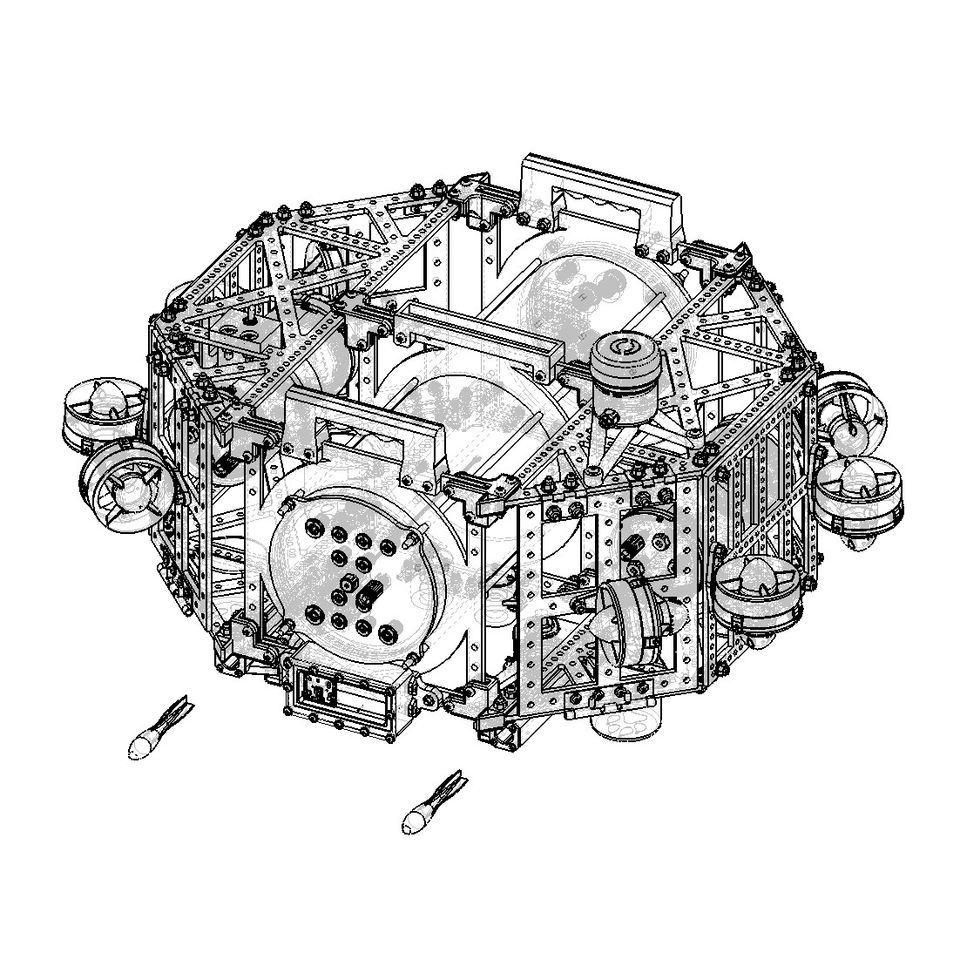

Mechanical

SeaWolf's Mechanical systems include a multi-hull waterproofing solution allowing power passthrough to it's omnidirectional thrusters, as well as a suite of manipulation systems including ratcheting torpedo launchers and a ball dropper, that enable SeaWolf to interact with it's environment.

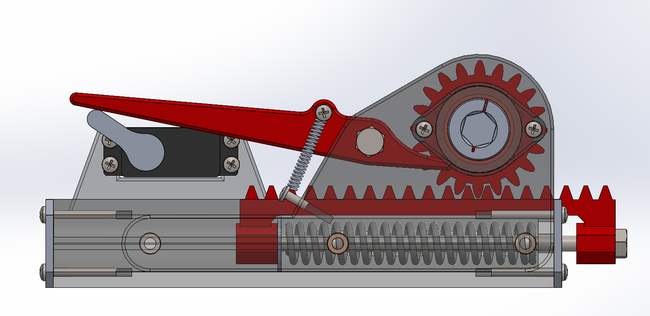

Ratcheting Torpedo Launcher

SeaWolf’s electro-mechanical torpedo launcher system consists of two identical launcher bodies each housing a watertight servo motor capable of actuating a lever arm holding a spring in compression until release. Several FDM printed projectiles were designed, with the chosen fusiform shape performing most favorably.

The design was chosen due its simplicity, which minimized the amount of electrical infrastructure needed and enabled iterative prototyping allowing for rapid development using an FDM printer while still meeting task requirements. The spring is drawn back using a ratcheting mechanism that allows for use of a more powerful spring than a hand-drawn system.

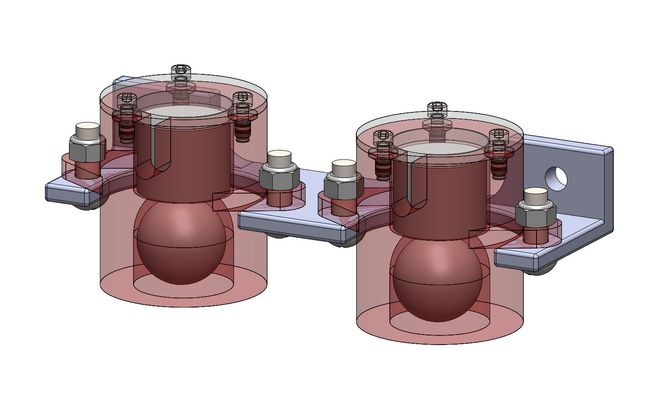

Marker Dropper

The dropper mechanism for SeaWolf VIII consists of three major components: a 5V electromagnet, a magnetic 440C stainless steel ball, and a 3D-printed housing. The electromagnet is seated in the upper portion of the housing and is snugly held in place with a screwed-on lid. The stainless steel ball, or marker, rests in the lower part of the housing. Current continuously runs through the electromagnet to create a magnetic field, which holds the marker secure in the housing.

When the time comes to drop the marker, the current is stopped and the marker is allowed to fall straight down out of the bottom of the housing. Two of these droppers attached to the bottom of SeaWolf VIII, enabling it to complete marker-related tasks.

Multi-Hull Waterproofing

SeaWolf makes use of three waterproof hulls, A cut-to size main hull with custom tapped endcaps that contains all of SeaWolfs electrical systems, and two Blue Robotics battery hulls that provide power to SeaWolfs systems.

SeaWolfs Multi-Hull system allows for rapid replacement of spent batteries, and provides more room in the main hull for custom electronics systems.

Omnidirectional Motors

SeaWolf’s 8 BlueRobotics T200 3-Phase motors are strategically arranged to provide SWVIII with a full 6 degrees of freedom, allowing it to rotate and move in any direction from any nmposition or orientation

Software

Rust

SeaWolf’s higher-level software is written in the Rust programming language. This code base interfaces with the control board, main electronics board, and peripheral devices to coordinate missions.

We use Rust because it offers:

- High performance comparable to C/C++

- A powerful type system and compiler capable of catching many errors at compile time

- Official tooling for building, testing, and documentation

- Modern language features

- Excellent documentation

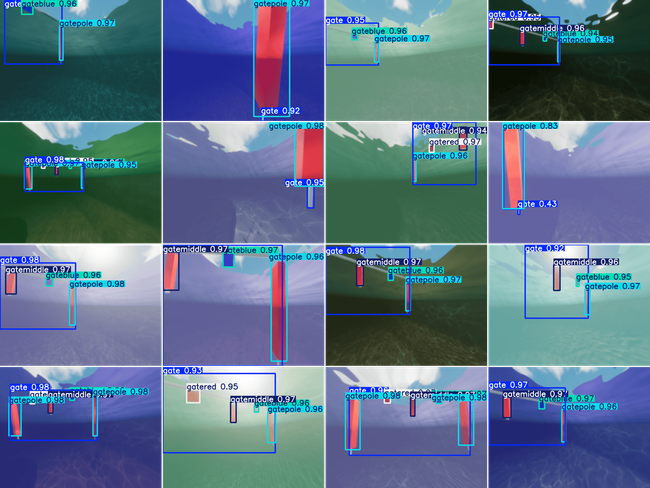

Computer Vision

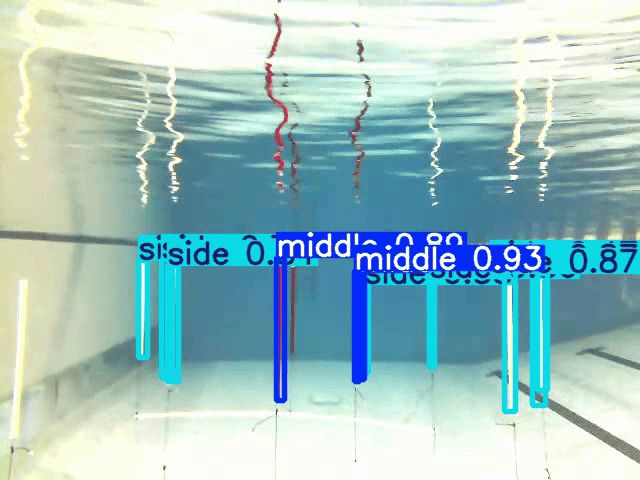

We use a combination of traditional and machine learning based computer vision pipelines.

Traditional CV utilizing edge and contour detection is suitable for simple tasks, such as following a marked path.

For tasks with complex features, neural networks are more suitable. They enable extracting distinct features in complex images, such as torpedo targets. We use the YOLOv5 nano model.

Custom Simulator

Our simulator was built in-house using the Unity game engine.

It features:

- Synthetic data generation:

- Realistic water

- Domain randomization

- Automatic bounding boxes & segmentation masking

- Communication with our rust code base

- Integration with our virtual control board